The Premier Aluminum Llc PDFs

Table of ContentsSome Known Details About Premier Aluminum Llc Premier Aluminum Llc Can Be Fun For EveryoneThe Best Strategy To Use For Premier Aluminum LlcThe Only Guide to Premier Aluminum Llc

(https://chartreuse-ixora-611.notion.site/Top-Aluminum-Casting-Company-Premier-Aluminum-LLC-15a1deb772b580b6adecd254a06068ca?pvs=4)Typically, a purchaser's primary duty was to discover professional and responsive vendors. Sometimes, buyers presumed that any kind of provider willing to contractually satisfy the acquisition requirement was certified. Nonetheless, using reduced expense and unqualified suppliers can trigger top quality issues, and lost time and money in the future. To help you with the procedure, here are some things to take into consideration when picking the appropriate metal casting distributor.

For instance, a firm that only uses the investment casting process will attempt to sell you on why that process is best for your application. What if utilizing the sand casting procedure is best for you and your requirements? Instead, try to find a supplier that offers a variety of casting procedures so the ideal alternative for YOU is chosen

If functioning with a solitary source for all of your casting needs is necessary to you, the supplier requires to be diverse in its abilities. When integrated with other integrated capabilities, this can help simplify and press the supply base. When choosing the best spreading vendor, careful factor to consider should be offered to high quality, service, and rate.

Little Known Questions About Premier Aluminum Llc.

Purchasers significantly pick casting providers who have machining capacities. This can prevent conflict if issues are found during machining. If a 3rd event is machining, it may lead to "finger-pointing" about that is at mistake. Is it a casting issue or a machining concern? If the spreading distributor finds a problem during machining, the trouble is fixed quicker with no disagreement over whose fault it is.

What do you need from your casting vendor? Are you looking for someone to just deliver a metal element to your doorstep or do you need a lot more?

Some foundries are limited or specialized. Make sure the provider can satisfy all your product or go right here alloy needs to remove the demand for multiple suppliers.

Excitement About Premier Aluminum Llc

Research the supplier's web site. Talk with a sales representative or company associate. Ask a great deal of questions. See their facility. Obtain an understanding of what they can do for you and if you can see yourself building a strong, common connection with them.

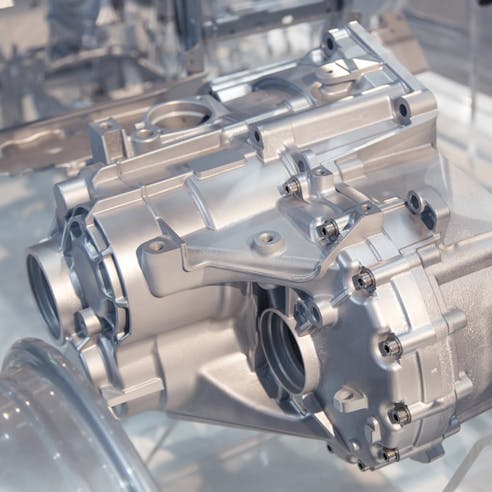

Light weight aluminum is also lightweight and has excellent corrosion resistance, making it excellent for applications where weight and sturdiness are necessary aspects. Furthermore, light weight aluminum spreading is a cost-efficient approach of manufacturing, as it requires less power and resources than various other approaches. Iron casting, on the other hand, involves putting molten iron into a mold to produce a wanted form.

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Iron spreading is additionally able to endure heats, making it ideal for usage in applications such as engine components and commercial equipment. Nonetheless, iron spreading can be more costly than light weight aluminum spreading because of the higher cost of basic materials and the energy called for to thaw the iron. When determining in between aluminum spreading and iron spreading, it is very important to take into consideration the specific requirements of the application.

In verdict, both light weight aluminum casting and iron casting have their own unique advantages and negative aspects. There are three sub-processes that fall under the category of die spreading: gravity die casting (or permanent mold spreading), low-pressure die spreading and high-pressure die spreading. To get to the finished item, there are 3 main alloys utilized as die casting product to choose from: zinc, light weight aluminum and magnesium.